- Home Page

- Company Profile

-

Our Products

- Chains

- Mining Chains and Accessories

- Mining Chains And Accessories

- Power-Chains & Connectors for Scraper Conveyor

- Power - Chains & Connectors for Scraper Conveyor

- Bucket Elevator Chains & U Links

- Cement - Bucket Elevator Chains & U Link

- Shipbuiling Electrically Welded Studless Link Anchor Chains

- Lifting Short Link Chains

- Lifting Round Steel Link Chains for Hoist Per DIN 5684

- Grade 80 T8 Calibrated Chain 6216 - 1982

- Grade 80 T8 Non Calibrated Chain

- Grade 30 L3 Calibrated Chain 2429

- Grade 30 L3 Calibrated Chain as per DIN 763

- Stainless Steel Chain

- Transporting Trailers & Shipping Containers

- Non Skid Tyre Chain

- Compensating Chains with Jute Rope Inlaid PVC Coated

- Cranes

- Double Girder EOT Crane

- Single Girder Eot Crane

- Manually Operated Crane

- Underslung Crane

- Jib Crane

- Crane Kits

- Gantry & Semi Gantry Crane

- Light Profile Crane

- Jib Crane

- HOT Cranes

- Wall Traveling Crane

- Articulated Jib Crane

- Transfer Trolley

- Grab Bucket

- Single Girder EOT Cranes

- Lifting Beams & Other Attatchments

- Wire Rope Hoist

- Solar Power Plant

- Chains

- Brochure Download

- Contact Us

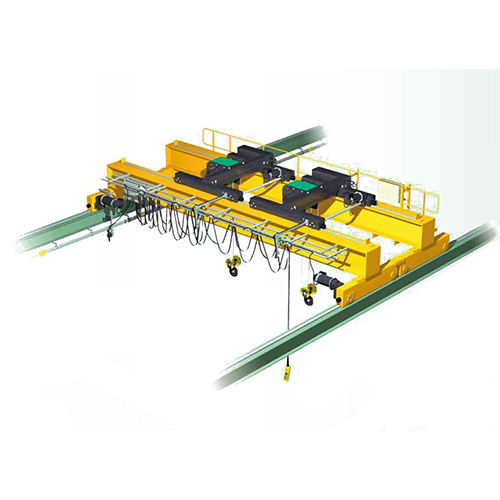

Single Girder EOT Cranes

Product Details:

- Crane Total Weight Depends on capacity and span (Customizable)

- Condition New

- Trolley Travel Speed 10-15 m/min

- Feature High efficiency, Smooth operation, Low maintenance

- Crane Traveling Speed 15-20 m/min

- Recommend Power 3 kW to 25 kW

- Material Mild Steel (MS), IS 2062/IS 807 Grade

- Click to view more

X

Single Girder EOT Cranes Price And Quantity

- 1 Piece

- Electro-hydraulic/AC electromagnetic brake

- Below 85 dB

- Box Type/Plate Type

- Forged Steel/EN8

- -10°C to +50°C

- IS 3177 / IS 807

- Yellow or as per requirement

- Class II/III (Medium - Heavy)

- On-site installation support available

- Electric Wire Rope Hoist

- 380/415 V AC, 3 Phase, 50 Hz

- Electric

- Anti-corrosive epoxy paint

Single Girder EOT Cranes Product Specifications

- Pendant/Remote/Cabin

- 1 Ton to 20 Ton

- Provided for over-lifting and lowering

- Depends on capacity and span (Customizable)

- Warehouses, Workshops, Assembly lines, Manufacturing

- New

- Single Girder EOT Crane

- 1 Ton to 20 Ton

- Included in control panel

- 6 m to 18 m (Customizable)

- High efficiency, Smooth operation, Low maintenance

- Mild Steel (MS), IS 2062/IS 807 Grade

- 10-15 m/min

- Depends on hoist, typically 4-8 m/min

- 3 kW to 25 kW

- 15-20 m/min

- 5 m to 30 m (Customizable)

- Electro-hydraulic/AC electromagnetic brake

- Below 85 dB

- Box Type/Plate Type

- Forged Steel/EN8

- -10°C to +50°C

- IS 3177 / IS 807

- Yellow or as per requirement

- Class II/III (Medium - Heavy)

- On-site installation support available

- Electric Wire Rope Hoist

- 380/415 V AC, 3 Phase, 50 Hz

- Electric

- Anti-corrosive epoxy paint

Single Girder EOT Cranes Trade Information

- Per Day

- 7 Days

- All India

Product Description

Since inception in 1982, we have been instrumental in offering a wide range of Single Girder EOT Cranes. The offered cranes are extensively demanded in industries to easily lift and transport the bulk or heavy materials with utmost ease at the desired place within installed premises. Manufactured by our dexterous professionals using quality-tested components and sophisticated techniques, these cranes are also checked on defined quality parameters to assure their optimum performance. Moreover, we are offering these Single Girder EOT Cranes to the clients in different technical specifications at the lowest prices.

Product Key Features:

Product Key Features:

- Easy to operate

- Rugged design

- Excellent load bearing ability

- Anti-corrosive surface

Product Specification

| Capacity (t) | 1, 2, 3, 5, 10(8) | |||||

| Span (m) | 7.5-31.5 | |||||

| Crane travelling mechanism | Travelling speed | 20 | 30 | 45 | 60 | |

|

| Speed ratio | 58.78 | 39.38 | 26.36 | 19.37 | |

|

| Motor | Model | ZDY21-4 | ZDR100-4 | ||

|

|

| Power | 2x0.8kw | 2x1.5kw | ||

|

|

| Turning speed | 1380 | |||

| Lifting mechanism | Hoist model | EOTC 17 | ||||

|

| Lifting speed (m/min) | 8, 8/0.8; 7, 7/0.7 | ||||

|

| Lifting height (m) | 6, 9, 12, 18, 24, 30 | ||||

|

| Travelling speed | 10, 20, 30 | ||||

|

| Motor | Cone Squirrel-cage | ||||

| Duty Class | A3-A4 | |||||

| Power source | 380V 50HZ 3 phase (or according to your standard) | |||||

| Wheel diameter | 270mm | |||||

| Width of rail top | 37-70mm | |||||

Key Features and Durability

These Single Girder EOT Cranes are built from IS 2062/IS 807 grade mild steel, ensuring durability under demanding industrial conditions. The anti-corrosive epoxy paint finish enhances longevity even in challenging environments. Forged steel wheels, robust end carriage design, and premium braking systems add to the cranes reliability and reduced maintenance needs.

Customizable Performance to Suit Your Needs

With lifting capacities ranging from 1 to 20 tons, spans up to 30 meters, and lifting heights between 6 and 18 meters, these cranes can be tailored to your specific applications. Power recommendations can be adapted up to 25 kW, and the color or finish can be customized as required.

Safety and Support You Can Trust

Each crane is equipped with limit switches for over-lifting and lowering, as well as an emergency stop in the control panel. Users can operate the crane via pendant, remote, or cabin controls. Our team offers complete on-site installation support, ensuring a seamless and secure setup at your facility.

FAQs of Single Girder EOT Cranes:

Q: How does the electric wire rope hoist enhance the performance of a single girder EOT crane?

A: The electric wire rope hoist provides smooth and efficient lifting, combined with precise control over load movement. Its robust design is suitable for medium and heavy-duty tasks, ensuring high reliability and conformity to IS standards.Q: What are the main benefits of using anti-corrosive epoxy paint and forged steel wheels?

A: Anti-corrosive epoxy paint protects the crane from rust and harsh environments, prolonging lifespan and reducing maintenance frequency. Forged steel wheels enhance durability and allow smooth movement of the crane along its track, even under heavy loads.Q: When is on-site installation support provided, and what does it include?

A: On-site installation support is available upon delivery and includes assembly, alignment, commissioning, and testing of the crane. This ensures your equipment is properly installed and operational as per safety standards.Q: Where can these single girder EOT cranes be used effectively?

A: They are ideal for use in warehouses, workshops, assembly lines, and various manufacturing environments where precise, safe, and efficient material handling is needed for loads ranging from 1 to 20 tons.Q: What is the process to customize the cranes span, lifting height, and capacity?

A: Customization starts with a consultation to assess your facilitys requirements, followed by design modifications according to your specified span (up to 30 m), lifting height (618 m), and capacity (120 tons). Final specifications are confirmed before manufacturing and delivery.Q: How is safety ensured during crane operation?

A: Safety features include limit switches to prevent over-lifting or lowering, emergency stop functionality, and robust electro-hydraulic or AC electromagnetic brakes. Operators can also choose between pendant, remote, or cabin controls for safer operation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email