- Home Page

- Company Profile

-

Our Products

- Chains

- Mining Chains and Accessories

- Mining Chains And Accessories

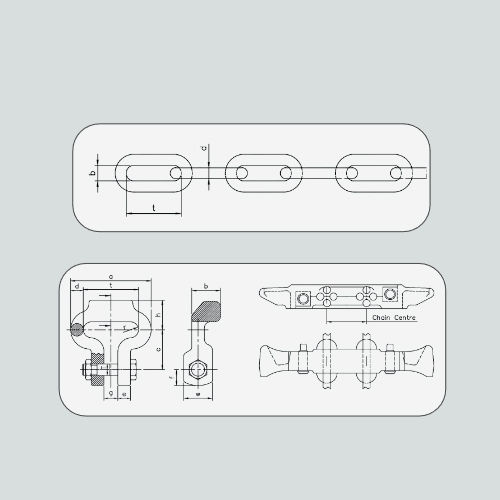

- Power-Chains & Connectors for Scraper Conveyor

- Power - Chains & Connectors for Scraper Conveyor

- Bucket Elevator Chains & U Links

- Cement - Bucket Elevator Chains & U Link

- Shipbuiling Electrically Welded Studless Link Anchor Chains

- Lifting Short Link Chains

- Lifting Round Steel Link Chains for Hoist Per DIN 5684

- Grade 80 T8 Calibrated Chain 6216 - 1982

- Grade 80 T8 Non Calibrated Chain

- Grade 30 L3 Calibrated Chain 2429

- Grade 30 L3 Calibrated Chain as per DIN 763

- Stainless Steel Chain

- Transporting Trailers & Shipping Containers

- Non Skid Tyre Chain

- Compensating Chains with Jute Rope Inlaid PVC Coated

- Cranes

- Double Girder EOT Crane

- Single Girder Eot Crane

- Manually Operated Crane

- Underslung Crane

- Jib Crane

- Crane Kits

- Gantry & Semi Gantry Crane

- Light Profile Crane

- Jib Crane

- HOT Cranes

- Wall Traveling Crane

- Articulated Jib Crane

- Transfer Trolley

- Grab Bucket

- Single Girder EOT Cranes

- Lifting Beams & Other Attatchments

- Wire Rope Hoist

- Solar Power Plant

- Chains

- Brochure Download

- Contact Us

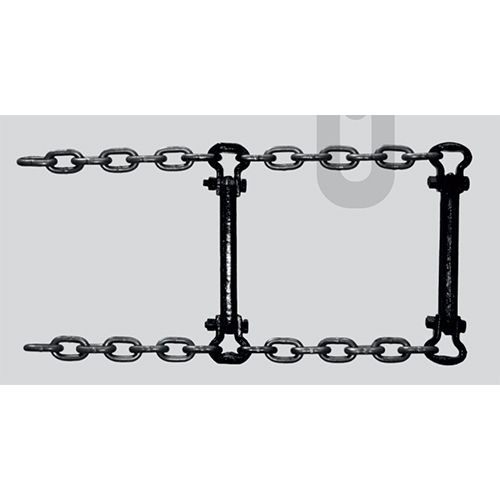

Mining Chains and Accessories

Product Details:

- Material Metal

- Metal Type High Grade Manganese Steel for GR. B Chain and Ni Cr Moly Steel for Gr. C Chain

- Product Type Mining Chains and Accessories

- Color Black

- Click to view more

X

Mining Chains and Accessories Price And Quantity

- 10 Piece

Mining Chains and Accessories Product Specifications

- Black

- Metal

- Mining Chains and Accessories

- High Grade Manganese Steel for GR. B Chain and Ni Cr Moly Steel for Gr. C Chain

Mining Chains and Accessories Trade Information

- 100 Piece Per Week

- 7 Days

Product Description

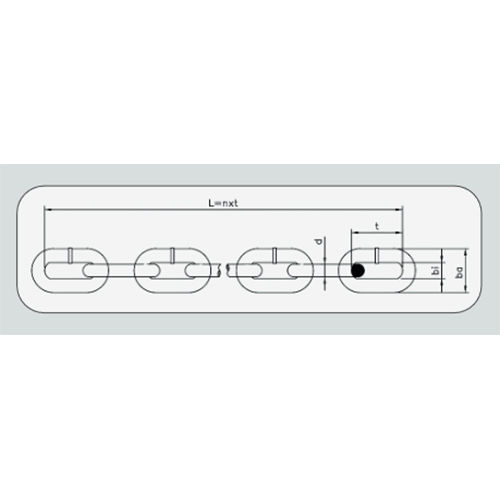

Mining Chains for use with Conveyors or Haulages are supplied conforming to specifications IS:3948, DIN: 22252 & DIN:20637 or to conform to any other special requirement of customer.

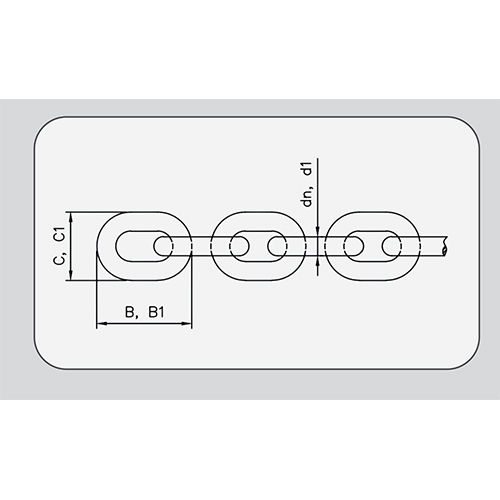

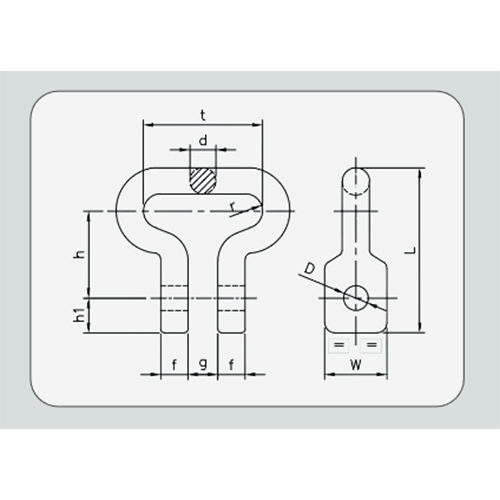

SPECIFICATION:

- Material: High Grade Manganese Steel for GR. B Chain and Ni Cr Moly Steel for Gr. C Chain

- Heat Treatment: Hardened and Tempered

- Process of Manufacture: Resistance Butt Welded up to 20 mm Dia and Flash Butt Welded 22 mm Dia and above

- Delivery condition: Chains are calibrated & supplied in Matched pairs

| All dimension in mm |

|

|

|

|

|

|

|

| |

| Nominal chain size | 14 x50 | 18 x 64 | 19 x 64.5 | 22 x 86 | 24 x 86 | 26 x 92 | 30 x 108 | 34 x 126 | |

| Material diameter and tolerance | 14 /+ 0.4 | 18 -/+ 0.5 | 19 -/+ 0.5 | 22 -/+ 0.7 | 24 -/+ 0.8 | 26 -/+ 0.8 | 30 -/+ 0.9 | 34 -/+ 1.0 | |

| Pitch and tolerance | 50 -/+ 0.5 | 64 -/+ 0.6 | 64.5 -/+ 0.6 | 86 -/+ 0.9 | 86 -/+ 0.9 | 92 -/+ 0.9 | 108 -/+ 01.0 | 126 -/+ 1.0 | |

| Outside width (max) | 48 | 60 | 63 | 74 | 79 | 86 | 98 | 109 | |

| Inside width (min) | 17 | 21 | 22 | 26 | 28 | 30 | 34 | 38 | |

| Test force (KN) | Gr B | 150 | 250 | 280 | 380 | 450 | 530 | 710 | 1160 |

| Gr C | 200 | 330 | 360 | 490 | 580 | 680 | 900 | 1450 | |

| % Total elongation At test force (max) | Gr B | 1.4 | 1.4 | 1.4 | 1.4 | 1.4 | 1.4 | 1.4 | 1.4 |

| Gr C | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | |

| Mini breaking force (KN) | Gr B | 190 | 320 | 360 | 480 | 570 | 670 | 890 | 1450 |

| Gr C | 250 | 410 | 450 | 610 | 720 | 850 | 1130 | 1790 | |

| & total elongation at break min | 12% minimum as per IS, 14 % minimum as per DIN | ||||||||

| Bend test deflection in mm BS, ISO and IS Din | 11 | 14 | 15 | 18 | 20 | 21 | 24 | 27 | |

| Approximate weight per meter Kg | 4.0 | 6.6 | 7.0 | 9.6 | 11. | 13.9 | 18.4 | 22.9 | |

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free